Hartel International is now the official sales representative for DEMAN US:

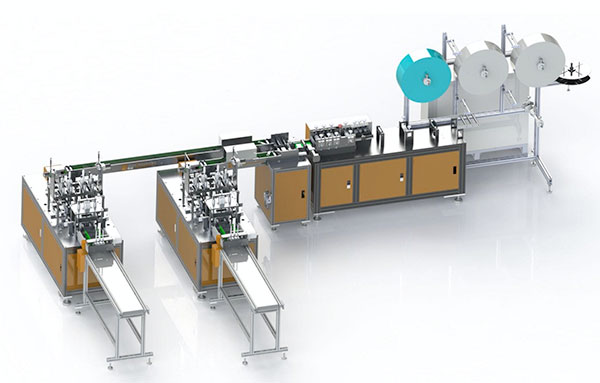

N95, KN95 and Normal Mask Making Production Lines

China now makes 200 million face masks a day — more than twenty times the amount it made at the start of 2020. The leap has been spurred by the outbreak of COVID-19 caused by the Novel Coronavirus. The masks include the lightweight ones that people like to wear in the hope of protection against coronavirus as well as the heavy-duty N95 masks used by health-care workers. But that’s still not nearly enough to meet local demands as well as global orders. A scramble is now underway in fill this urgent need, and mask factories are “running at 110 percent capacity,” say authorities.

This machine is mainly used for the automatic formation of flat masks: the fabric is driven by rollers, and automatically folded and hemmed; the length of the nose bridge is pulled and unrolled, cut to length and imported into the hemmed fabric, bilaterally Ultrasonic welding to the seal, then ultrasonic side sealing, and cutting: the final mask is formed by ultrasonic welding.

The KN95 mask production line adheres to the corporate philosophy of “technology creates excellence”. The KN95 mask is composed of 6 layers of special filtering non-wowen, which meets the NIOSH standard filtration rate of 95%. It can effectively filter certain microbial particles (entering viruses, bacteria, etc.), avoid cross-infection of droplets and protect human health.

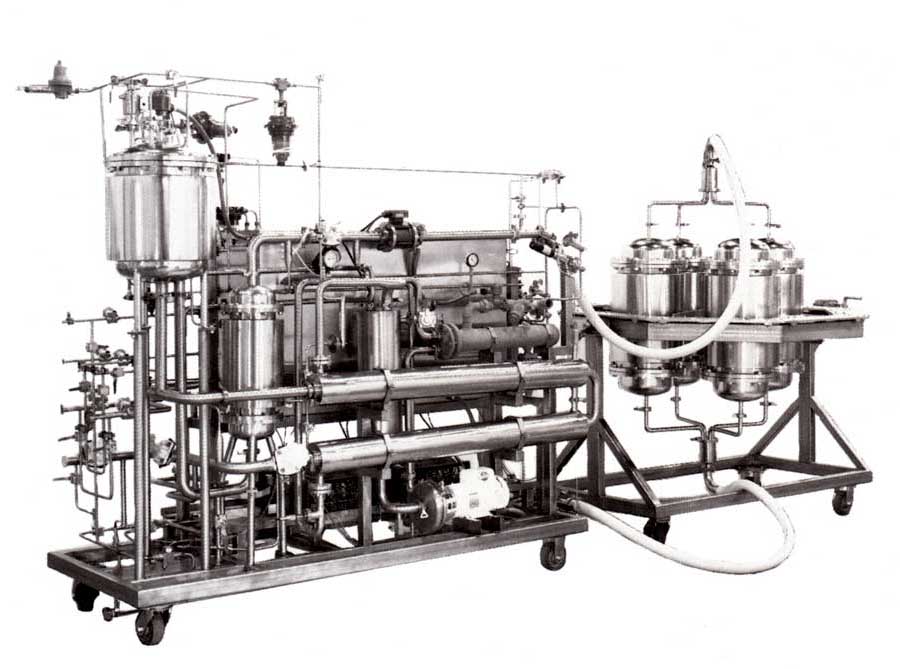

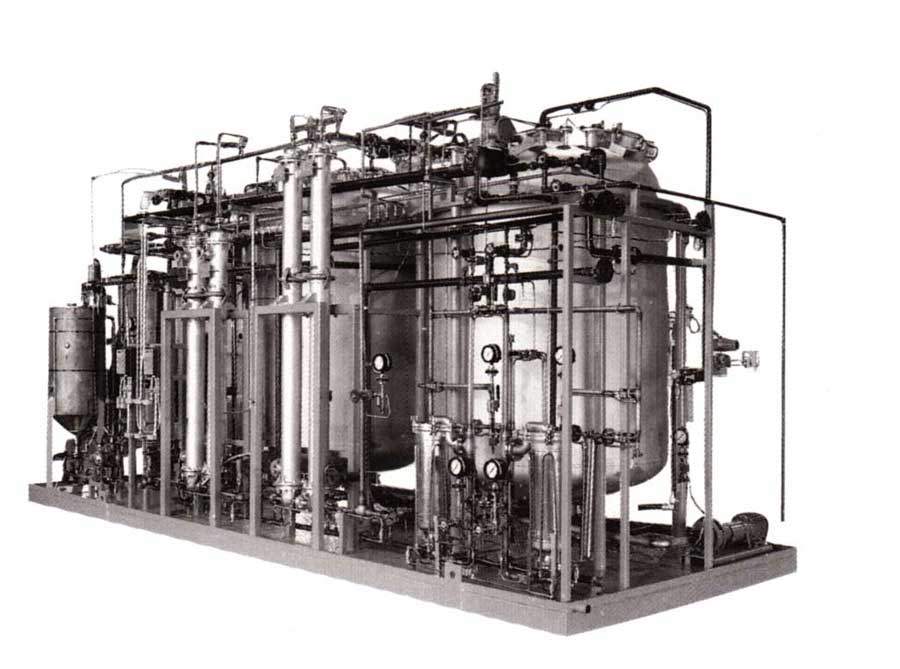

Processing Systems

Single Source Responsibility

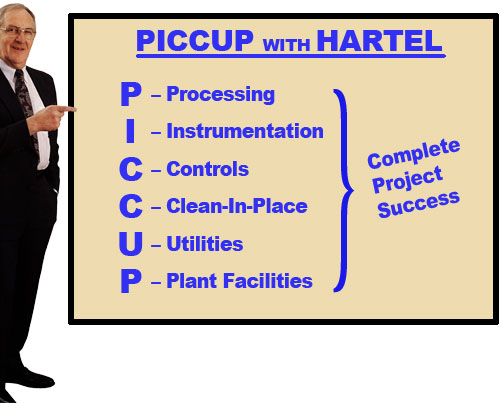

These advantages and more:

- Latest technology in controls and instrumentation

- Can integrate with any control system

- Programming and software capabilities

- Current technology for fabrication and manufacturing

- Products meet all regulatory agency standards

- Explosion-proof systems are available

- Computer aided design (CAD)

- Reliable service by trained technicians and project managers

- Personnel available within 24 hours

- Extensive experience in process industry applications

- Complete system responsibility