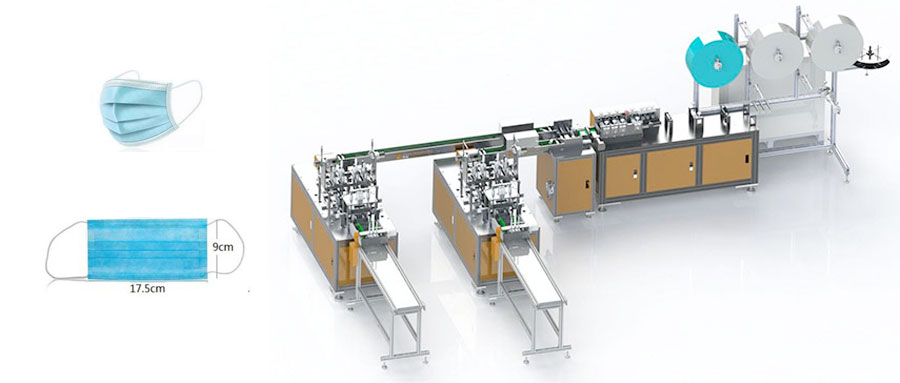

This machine is mainly used for the automatic formation of flat masks: the entire roll of fabric is driven by rollers after unwinding, and the fabric is automatically folded and hemmed; the entire length of the nose bridge is pulled and unrolled, cut to length and imported into the hemmed fabric, bilaterally Ultrasonic welding to the seal, then ultrasonic side sealing, cutting with a cutter: the mask is conveyed to the two mask earband welding stations through an assembly line, and the final mask is formed by ultrasonic welding. When the mask is made, it passes the assembly line. Conveyed to flat belt line for collection.

Specifications

Machine Size: 7000mm(L)×4000mm(L)×2000mm(H)

Equipment weight: ≤1500kg

Ground bearing capacity: > 300KG / e

Working power: 230/400V 3P, 50Hz

Compressed air: 0.6 – 0.7MPa,mit Durchsatz von ca.300L / min

Perating environment: temperature 1035 ℃, humidity 5-35% HR, no flammable, corrosive gas, no powder (cleanliness no less than 100,000).

Delivery Time: 45-60 Days

Container Bedarf: 20GP x 1

Guarantee: 24 months with 2 shift running

Price Valid time: 1 Month

Electrical Parts:

Main Motor: Simens

Frequency converter: Schneider/Omron

Low voltage Parts: Schneider

Temperature Measurement: OmRon / Fuji

Voltage: 230/400V 3P, 50Hz

PLC: Omron

Touchpan: Simens / Schneider /Omron

Manufacturing Company Overview

Manufacturing Company Overview

Deman Machine Group is an international manufacturer with more than 250 employees worldwide. 4 Branches are located in Germany, China, USA, Egypt. Since 2005, we have moved our production base to China. With a professional design team we are famous in different machines and in different industrial areas. more than 30 engineers are always focused on offering the stable running and long service life of machines to our customers. Over fifteen years of experience in China, our factory in China has already received full support as a high-tech company in government.