KN95 mask is composed of 6 layers of special filtering non-wowen, which meets the NIOSH standard filtration rate of 95%. It can effectively filter certain microbial particles (entering viruses, bacteria, etc.), avoid cross-infection of droplets and protect human health.

The KN95 mask production line adheres to the corporate philosophy of “technology creates excellence”, integrates the essence of decades of machine manufacturing experience, uses optimized design technology, and uses automatic control systems across the entire line, servo tracking welding, effectively reducing energy consumption to a minimum. Increased efficiency to a higher level. This production line has a leading position in China and is currently the most promising investment project.

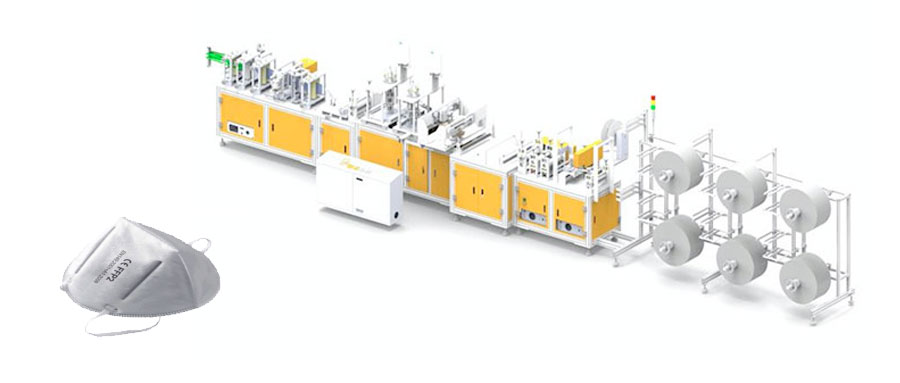

Description of the production process

The production line has 6 cloth trays and a nasal bridge unwinding tray, which can produce up to 6 layers of N95 masks. Each unwinding has a lack of material alarm and tension adjustment. The rolls are stacked in, and at the same time they are placed in the bridge of the nose. Weld multiple layers of fabric together by ultrasonic welding, and press out various patterns, and then punch out the valve hole of the cover. Carry out trademark printing and automatically weld the earrings, then fold, weld, cut, and finally put the finished product into the box, and fold it away.

Flow diagram

Nowoven insertion → Nose bridge → Welding embossing → Punch valve hole → Traction → Printed trademark→ Welding ear bands → Folding → Welding edges → Cut-out → Close-up → Finished products in theBox

Production capacity: 60-80 pcs/min

Specifications

Machine Units and Quantity

- Unwinding mechanism (6 stations): 1 set

- Nose bridge strip unwinding mechanism: 1 set

- Nose bridge straightening mechanism: 1 set

- Nose bridge driving and cutting mechanism: 1 set

- Nose bridge strip placement mechanism: 1 set

- Flow welding device: 1 set

- Valve hole cutting mechanism: 1 set

- One set of traction mechanism: 1 set

- Two sets of trademark agencies: 1 set

- Two sets of automatic welding ear strap mechanism: 2 sets

- A set of automatic servo shearing mechanism for welding ear band: 2 Stück

- One set of folding mechanism: 1 set

- Welding edge mechanism: 1 set

- A set of automatic servo tracking shearing mechanism for welding edge: 1 set

- Cutting mechanism: 1 set

- A set of fast conveying mechanism: 1 set

- A set of border collection agencies: 1 set

- Electrical control system: 1 set

KN95 Detailed composition of KN95 mask production line

- Unwinding system: 1set

- Unwinding station: 6 sets

- Out of material alarm detection: 6 sets

- Nowoven roll diameter: Φ60–Φ80

- Roll diameter: Φ600

- Roll width: 250mm

- Nose bridge strip unwinding mechanism: 1 set

- Unwinding station: 1 set

- Out of material alarm detection: 1 set

- Nowoven roll diameter: Φ30—Φ50

- Roll diameter: Φ350

- Roll width: 1000mm

- Nose bridge straightening mechanism: 1 set

- Calibration number: 7 rounds

- Wheel diameter: Φ22

- Nose bridge driving and cutting mechanism: 1 set

- Cutting type: intermittent touch wheel

- Power mechanism: Spindle drive

- Nose bridge strip placement mechanism: 1 set

- Insertion form: push plate type

- Power mechanism: Spindle drive

- Pattern welding device: 1 set

- Welding method: Ultrasonic: 1 set

- Welding Oscillator 20K: 1 set

- Valve hole cutting mechanism: 1 set

- Cutting method: Ultrasound

- Cutting wheel diameter: Φ83

- One set of traction mechanism: 1 set

- Traction roller diameter: Φ83mm

- Power mechanism: Spindle drive

- Logo Agency: 2 sets

- Printing type: Ink

- Printing power: pneumatic

- Automatic welding ear band mechanism: 2sets

- Welding method: Ultrasonic

- Welding Oscillator: 20K

- A set of automatic servo shearing mechanism for welding ear band

- Power mechanism: Servo

- Servo power: 750W

- One set of folding mechanism: 1 set

- Roller diameter: Φ83mm

- Power mechanism: Spindle drive

- Welding edge mechanism: 1 set

- Welding method: Ultrasonic

- Welding Oscillator: 15K

- Power: Pneumatic

- A set of automatic servo tracking shearing mechanism for welding edge

- Power mechanism: Servo

- Servo power: 750W

- Cutting mechanism: 1 set

- Cutting roller diameter: Φ83mm

- Power mechanism: Spindle drive

- Fast conveying mechanism: 1 set

- Conveying form: 1 set

- Power mechanism Spindle drive: 1 set

- A set of border collection agencies: 1 set

- Edge roller diameter: Φ60mm

- Power mechanism: Spindle drive

- Electrical control system: 1 set

- Control method: interface operation

- Screen size: 7 ”

- Power supply voltage: 220V

- Spindle control mode: Servo control

- Servo power: 1.5KW

Manufacturing Company Overview

Manufacturing Company Overview

Deman Machine Group is an international manufacturer with more than 250 employees worldwide. 4 Branches are located in Germany, China, USA, Egypt. Since 2005, we have moved our production base to China. With a professional design team we are famous in different machines and in different industrial areas. more than 30 engineers are always focused on offering the stable running and long service life of machines to our customers. Over fifteen years of experience in China, our factory in China has already received full support as a high-tech company in government.